German software developer SCHOTT SYSTEME GmbH launches the latest version of its CAD/CAM software Pictures by PC.

Toolmaking essentially benefits from automatic mold separation at edge and silhouette curves, which is possible for both inner and outer surfaces. A mesh offset has been added to the existing hybrid modeler for volumes, areas and meshes, which is ideal for generating wall thicknesses of imported STL models. Also new is the cutting of mesh bodies on curves.

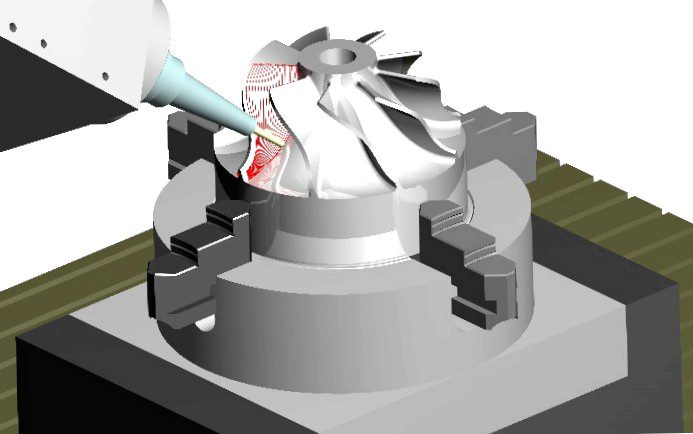

HPC (High Performance Milling): Trochoidal 3D roughing supports dynamic and rapid material removal, even of hard mold materials. 3D spiral finishing allows the machining of steep and flat areas of a mold with a single tool path, whose path spacing depends on the angle of the surfaces to be machined. Further improvements, such as 5-axis rotary roughing and 4-axis spiral finishing, reduce programming effort and machining time for parts to be machined on multiple sides.

The new 5-axis simulation from SCHOTT SYSTEME helps to detect possible collisions between the machine spindle, table, clamping parts and components without the need for a full machine simulation.

All these enhancements complement SCHOTT SYSTEME’s existing software tools for milling, engraving, wire EDM and turning. The support for this software is free of charge, all standard postprocessors are included and there are no running costs.

No maintenance fees since 1984

With the purchase of our Pictures by PC CAD / CAM software you acquire a perpetual license. This means that the license can be used on one workstation with no time limit and no annual maintenance costs. The software is linked to the computer.

Transparent pricing

Linear pricing structure with no hidden costs. Post-processors for standard CNC controls are free of charge and can be generated and modified (by the user).

Free software support since 1984

Our customers receive free software support via e-mail and telephone, directly from our software development team (Mo. till Fri. 9 to 18 h).

We at 1st Mould manufacture aluminum molds for plastic injection molding. We mill our complex and highly accurate molds with Pictures by PC. What we particularly appreciate about Pictures by PC is the possibility to program routines that automate the creation of milling programs. Furthermore, it should be mentioned that all functions are stored in the source code, so that these can also be easily adapted. The support of Pictures by PC is very competent and helps quickly when questions about programming arise. Also with the updates of the software you notice that SCHOTT SYSTEME GmbH takes user requests and hints seriously and integrates them into the software.

We work at several workstations with the CAD/CAM software Pictures by PC, mainly to perform our machining tasks (we are a classic injection mold manufacturer). I find the support/service capabilities particularly impressive. I was always helped promptly, patiently, competently and in a friendly manner. The topics covered went much deeper than just the pure operation of the software. Suggestions are heard and will be considered in future versions. We look back on many years of cooperation with SCHOTT SYSTEME, and we consider Schott’s strong customer orientation to be an absolute added value.